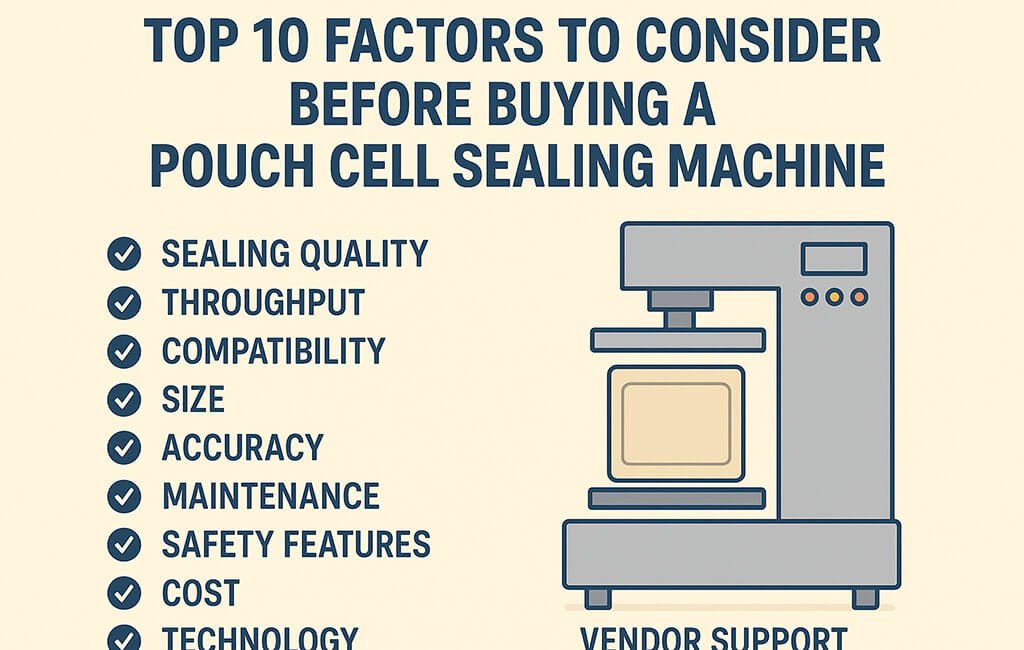

Selecting the right pouch cell manufacturing machine represents a critical decision that directly impacts production quality, throughput, and long-term operational efficiency. The sealing process determines cell integrity, electrolyte retention, and overall battery performance throughout its lifecycle.

This comprehensive guide examines ten essential factors that battery manufacturers must evaluate when investing in pouch cell sealing equipment. From thermal management specifications to format flexibility, each consideration plays a vital role in achieving consistent, high-quality sealed cells.

1. What Are the Essential Sealing Temperature Control Requirements?

Temperature uniformity across the sealing bar determines seal integrity and prevents localized overheating that can damage the aluminum laminate film. Modern sealing machines require precision temperature control within ±2°C across the entire sealing surface.

Key temperature specifications include:

- Operating range: 140-200°C for standard aluminum laminate films

- Ramp-up time: Less than 5 minutes to reach operating temperature

- Temperature zones: Minimum 2-4 independent control zones

- Thermal stability: ±1°C during continuous operation

Temperature monitoring systems should include real-time feedback loops with automatic adjustment capabilities. This ensures consistent seal quality across varying production speeds and ambient conditions.

2. Sealing Pressure Uniformity and Control Systems

Pressure distribution directly affects seal strength and prevents electrolyte leakage paths. Uneven pressure creates weak points that can fail during formation cycling or long-term use.

| Pressure Parameter | Specification Range | Application Notes |

|---|---|---|

| Applied Pressure | 0.3-1.5 MPa | Higher for automotive cells |

| Pressure Uniformity | ±5% across seal area | Critical for large-format cells |

| Pressure Control | Servo or pneumatic | Servo preferred for precision |

| Response Time | <100 ms | Ensures consistent contact |

Advanced systems incorporate load cells at multiple points along the sealing bar. This enables real-time pressure mapping and automatic compensation for bar deflection or wear.

3. How Does Cycle Time Impact Production Efficiency?

Cycle time encompasses heating, pressing, cooling, and material handling phases. Total cycle time directly determines hourly throughput and must align with upstream and downstream processes.

Typical cycle time breakdown:

- Material positioning: 2-3 seconds

- Sealing dwell time: 3-8 seconds

- Cooling phase: 2-4 seconds

- Material ejection: 1-2 seconds

High-speed machines achieve sub-10-second total cycle times through parallel processing stations or continuous motion designs. Consider future capacity requirements when evaluating cycle time specifications.

4. Format Flexibility and Changeover Requirements

Battery manufacturers typically produce multiple cell sizes and configurations. Quick changeover capability reduces downtime and enables flexible production scheduling.

Critical flexibility features include:

- Adjustable sealing bar width: 50-400mm typical range

- Programmable recipe storage: Minimum 100 product configurations

- Tool-free changeover mechanisms for common adjustments

- Automatic parameter recall linked to product identification

Modular tooling designs enable rapid format changes while maintaining precision alignment. Electronic position indicators and servo-driven adjustments eliminate manual setup variations.

5. Seal Quality Monitoring and Inspection Systems

Real-time quality monitoring prevents defective cells from progressing through subsequent production steps. Integrated inspection systems detect common seal defects immediately after the sealing process.

Essential inspection capabilities:

- Seal width measurement: ±0.1mm accuracy

- Visual defect detection: Wrinkles, contamination, incomplete seals

- Thermal imaging: Temperature uniformity verification

- Pressure profile recording: Force distribution documentation

Data logging systems should capture all process parameters for each sealed cell. This enables traceability and statistical process control implementation.

6. What Material Handling Features Ensure Safe Cell Processing?

Pouch cells require gentle handling to prevent internal damage or electrolyte shifting. Material handling systems must accommodate varying cell stiffness levels from pre-formation to aged cells.

Key handling specifications:

- Vacuum or edge-gripping mechanisms

- Adjustable grip force: 5-50N typical range

- Anti-static materials throughout contact surfaces

- Cushioned stops and guides

Automated loading and unloading systems should include cell presence detection and orientation verification. This prevents misaligned sealing attempts that could damage cells or tooling.

7. Thermal Management System Design

Consistent thermal performance requires robust cooling systems for both sealing bars and machine framework. Thermal expansion effects can significantly impact seal quality if not properly managed.

| Thermal System Component | Specification | Purpose |

|---|---|---|

| Cooling Capacity | 5-15 kW typical | Maintains stable operation |

| Coolant Temperature | 15-25°C | Prevents condensation |

| Flow Rate Monitoring | Real-time display | Ensures system health |

| Thermal Barriers | Ceramic or composite | Reduces heat transfer |

Water-cooled systems provide superior temperature stability compared to air cooling. Closed-loop chillers with filtration prevent contamination buildup that could affect heat transfer efficiency.

8. Safety Features and Compliance Standards

Pouch cell sealing machines must incorporate comprehensive safety systems to protect operators and prevent cell damage during upset conditions.

Mandatory safety features:

- Light curtains or physical guards around sealing area

- Emergency stop circuits meeting ISO 13850 requirements

- Two-hand control operation for manual modes

- Thermal overload protection on all heated elements

- Pressure relief mechanisms to prevent over-pressurization

CE marking or equivalent safety certification demonstrates compliance with machinery directives. Lockout/tagout provisions enable safe maintenance procedures.

9. Maintenance Requirements and Serviceability

Regular maintenance ensures consistent seal quality and prevents unexpected downtime. Machine design should facilitate routine service tasks without extensive disassembly.

Maintenance accessibility checklist:

- Sealing bar replacement time: Less than 30 minutes

- Heating element access: Front or side removal

- Wear parts inventory: Locally sourceable components

- Diagnostic interfaces: Built-in troubleshooting guides

- Calibration procedures: Documented intervals and methods

Predictive maintenance features such as cycle counters and wear indicators help schedule service during planned downtime periods. Remote diagnostic capabilities enable rapid technical support response.

10. Integration Capabilities with Production Lines

Modern battery production requires seamless integration between all process steps. Pouch cell sealing machines must communicate with upstream and downstream equipment for coordinated operation.

Standard integration requirements:

- Communication protocols: OPC-UA, Modbus TCP, EtherNet/IP

- MES connectivity: Production data upload capabilities

- Conveyor interfaces: Speed matching and accumulation control

- Recipe management: Centralized parameter distribution

Standardized data formats enable production analytics and quality tracking across the entire manufacturing line. Consider future automation upgrades when evaluating integration options.

Troubleshooting Common Sealing Defects

Understanding potential failure modes helps evaluate machine capabilities during the selection process. Robust equipment designs prevent or rapidly identify these common issues:

- Incomplete seals: Check temperature uniformity, pressure distribution, and dwell time settings

- Seal delamination: Verify material cleanliness, temperature ramp rates, and cooling profiles

- Wrinkled seals: Inspect material tension, alignment guides, and bar parallelism

- Contamination entrapment: Review clean room compatibility and material handling paths

- Thermal damage: Confirm temperature calibration and thermal barrier effectiveness

Process Optimization Considerations

Beyond equipment specifications, consider how different sealing approaches impact overall cell quality and production efficiency.

| Sealing Method | Advantages | Limitations |

|---|---|---|

| Side sealing only | Faster cycle time, simpler tooling | Requires pre-sealed top tabs |

| Three-side sealing | Complete in one operation | Complex bar geometry needed |

| Progressive sealing | Reduced thermal stress | Longer total cycle time |

| Ultrasonic sealing | Lower temperature operation | Limited thickness range |

Validation and Qualification Protocols

Establishing machine capability requires systematic validation during commissioning. Key validation tests include:

- Temperature mapping across all heating zones

- Pressure uniformity verification using pressure-sensitive film

- Seal strength testing per manufacturer specifications

- Burst pressure testing on sealed samples

- Accelerated aging studies on sealed cells

Document all validation results as baseline references for ongoing process monitoring. Regular revalidation ensures continued compliance with quality standards.

Conclusion

Selecting an appropriate pouch cell manufacturing machine requires careful evaluation of thermal control, pressure uniformity, cycle time, and integration capabilities. The sealing process directly impacts cell reliability and performance throughout the battery lifecycle.

Focus on equipment that provides consistent, verifiable seal quality while maintaining production flexibility. Consider both current production requirements and future capacity expansion when making investment decisions. Proper machine selection, combined with robust validation protocols, ensures reliable pouch cell production for automotive, energy storage, and consumer electronics applications.

Glossary

- Aluminum Laminate Film

- Multi-layer packaging material consisting of aluminum foil between polymer layers, used as the pouch cell casing

- Dwell Time

- Duration that sealing bars maintain pressure and temperature on the pouch material during the sealing cycle

- Formation Cycling

- Initial charge-discharge cycles that create the solid electrolyte interface (SEI) layer and stabilize cell capacity

- Seal Integrity

- Measure of seal completeness and strength, typically verified through burst testing or helium leak detection

- Tab Welding

- Process of ultrasonically joining current collector foils to external terminal tabs before pouch sealing

- Thermal Uniformity

- Temperature consistency across the sealing bar surface, critical for preventing localized hot spots or cold zones

- Degassing Port

- Temporary opening in the pouch seal that allows gas evacuation during formation before final sealing

- Servo Control

- Closed-loop positioning system providing precise, repeatable motion control for pressure application