Pouch cell production demands precise control across multiple manufacturing stages, from electrode preparation through final formation testing. Each process step introduces potential defect modes that can compromise cell performance, safety, and production yield.

Modern pouch cell manufacturing machine systems integrate automated quality control mechanisms, but understanding root causes and corrective actions remains essential for production engineers. This guide examines the most prevalent defects across slitting, tab welding, filling, and formation processes, providing actionable solutions based on equipment specifications and process parameters.

What Are the Critical Process Parameters for Pouch Cell Manufacturing Machine Operations?

Process parameter optimization forms the foundation of defect prevention in pouch cell production. Each manufacturing stage requires specific tolerances and control ranges to maintain product quality.

The following table outlines key parameters across major production stages:

| Process Stage | Critical Parameter | Typical Range | Application Notes |

|---|---|---|---|

| Electrode Slitting | Slit Width Tolerance | ±0.1-0.2mm | EV: ±0.1mm; ESS: ±0.2mm acceptable |

| Electrode Slitting | Web Tension | 50-150 N/m | Higher for thicker electrodes (>150μm) |

| Tab Welding | Ultrasonic Power | 300-800W | Al tabs: 300-500W; Ni tabs: 500-800W |

| Tab Welding | Weld Time | 0.2-0.8s | Shorter for consumer electronics |

| Electrolyte Filling | Vacuum Level | -95 to -99 kPa | Higher vacuum for high-viscosity electrolytes |

| Electrolyte Filling | Fill Volume Accuracy | ±0.5-1.0% | Tighter control for high-energy cells |

| Heat Sealing | Seal Temperature | 160-200°C | Lower for thin pouch materials |

| Formation | Initial Charge Rate | 0.05-0.1C | Lower rates for high-nickel cathodes |

Parameter selection depends on electrode chemistry, pouch material specifications, and target application requirements. Automotive applications typically demand tighter tolerances compared to stationary energy storage systems.

How Do You Identify and Resolve Electrode Slitting Defects in Pouch Cell Manufacturing Machine Systems?

Electrode slitting defects directly impact cell assembly quality and electrochemical performance. Common issues include edge burrs, width variations, and coating damage.

Burr formation occurs when blade sharpness degrades or cutting parameters drift from optimal ranges. Typical burr heights exceeding 10 micrometers can puncture separators during cell assembly, creating internal short circuits. Resolution requires blade inspection schedules based on material throughput rather than calendar time.

Width variation manifests as systematic drift or random fluctuations in slit electrode dimensions. Systematic drift typically indicates blade wear or thermal expansion in the slitting system. Random variations often trace to web tension instability or material feed irregularities.

Electrode Slitting Troubleshooting Checklist

- ☐ Verify blade sharpness using optical microscopy (replace at 20μm edge radius)

- ☐ Check web tension uniformity across width (±5% maximum variation)

- ☐ Confirm blade overlap setting (0.5-1.0mm typical for shear cutting)

- ☐ Inspect dust extraction system performance (minimum 95% capture efficiency)

- ☐ Validate material temperature stability (±2°C during slitting)

- ☐ Monitor blade vibration amplitude (<5μm peak-to-peak)

- ☐ Verify roller parallelism (0.02mm maximum deviation)

Edge dust generation represents another critical defect mode. Excessive dust contaminates downstream processes and can cause soft shorts in finished cells. Dust extraction systems must maintain consistent vacuum levels while avoiding electrode deformation.

What Causes Tab Welding Failures in Automated Pouch Cell Production?

Tab welding defects compromise current collection efficiency and mechanical reliability. Primary failure modes include insufficient weld strength, excessive heat damage, and misalignment.

Insufficient weld strength typically results from inadequate ultrasonic power transmission or contamination at the weld interface. Surface oxidation on aluminum tabs particularly impacts weld quality, requiring controlled atmosphere storage or inline surface treatment.

Heat damage manifests as polymer separator melting or active material delamination near weld zones. This defect becomes more prevalent with high-speed production lines where heat dissipation time decreases.

Tab Welding Configuration Comparison

| Welding Method | Advantages | Limitations | Typical Applications |

|---|---|---|---|

| Ultrasonic | No consumables, fast cycle time | Thickness limitations, noise generation | High-volume consumer cells |

| Laser | Precise control, minimal HAZ | Higher capital cost, safety requirements | Automotive pouch cells |

| Resistance | Mature technology, low cost | Electrode wear, inconsistent quality | Low-volume specialty cells |

Tab misalignment creates uneven current distribution and mechanical stress concentrations. Vision system integration enables real-time position correction, but mechanical fixture accuracy remains fundamental.

Electrolyte Filling and Wetting Defects: Root Causes and Solutions

Incomplete electrolyte wetting ranks among the most challenging defects to detect and correct. Manifestations include capacity fade, increased impedance, and localized heating during operation.

Vacuum filling systems must balance evacuation speed with electrolyte vapor pressure limits. Excessive vacuum levels can cause electrolyte component evaporation, altering the formulation and degrading performance.

The wetting process depends on electrode porosity, separator characteristics, and electrolyte surface tension. Pre-wetting with low-viscosity solvents can improve penetration but requires additional process steps and quality controls.

Electrolyte Filling Process Optimization

- Vacuum ramping profiles: Linear vs. stepped evacuation impacts void formation

- Temperature control: Higher temperatures reduce viscosity but increase evaporation

- Multi-stage filling: Partial fills with intermediate vacuum cycles improve uniformity

- Post-fill aging: Time and temperature combinations for complete wetting

Filling volume accuracy directly correlates with cell-to-cell consistency. Gravimetric dispensing systems provide superior accuracy compared to volumetric methods, particularly for temperature-sensitive electrolytes.

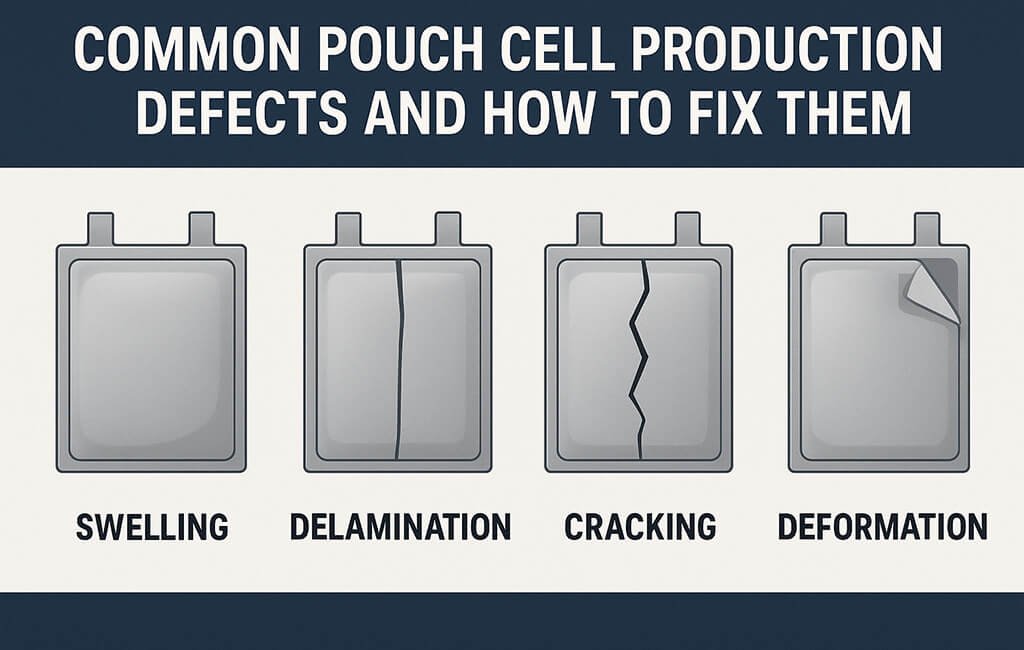

How Do You Prevent Pouch Sealing Defects in High-Volume Production?

Pouch sealing integrity determines long-term reliability and safety. Common defects include incomplete seals, excessive seal width variation, and material degradation.

Incomplete seals result from contamination, insufficient temperature, or inadequate pressure. Electrode material particles represent the primary contamination source, requiring careful handling and cleaning protocols.

Seal width variations affect cell dimensions and can compromise mechanical packaging requirements. Consistent heat distribution across sealing bars proves critical for uniform results.

Sealing Parameter Optimization Matrix

| Pouch Thickness | Seal Temperature | Dwell Time | Applied Pressure |

|---|---|---|---|

| 113μm | 165-175°C | 2.0-2.5s | 0.4-0.5 MPa |

| 153μm | 175-185°C | 2.5-3.0s | 0.5-0.6 MPa |

| 200μm | 185-195°C | 3.0-3.5s | 0.6-0.7 MPa |

Material degradation during sealing manifests as polymer chain scission or adhesive layer separation. Precise temperature control and rapid cooling prevent excessive thermal exposure.

Formation and Testing Defects: Early Detection and Correction

Formation represents the final opportunity to identify and potentially correct production defects. Voltage anomalies, capacity shortfalls, and self-discharge variations indicate upstream process issues.

Voltage anomalies during initial charging often trace to tab welding defects or electrolyte distribution problems. Incremental capacity analysis techniques can differentiate between these root causes.

Capacity shortfalls may result from insufficient electrolyte, poor wetting, or electrode manufacturing variations. Statistical process control charts help identify systematic versus random variations.

Formation Defect Diagnostic Flowchart

- High initial impedance → Check tab weld integrity and electrolyte filling completeness

- Voltage plateau irregularities → Investigate electrode coating uniformity

- Excessive temperature rise → Verify separator integrity and internal short circuits

- Capacity below specification → Analyze electrode loading and electrolyte volume

- High self-discharge → Examine sealing quality and metallic contamination

Self-discharge testing requires extended aging periods but provides critical quality assurance. Cells exceeding specifications often contain metallic particles or exhibit compromised separator integrity.

Quality Control Integration Strategies for Pouch Cell Manufacturing Machine Lines

Effective defect prevention requires integrated quality control systems throughout the production line. Inline inspection technologies enable real-time detection and correction.

Vision systems monitor electrode alignment, tab position, and seal integrity. Specification limits must account for measurement uncertainty while maintaining process capability.

Data integration platforms correlate defects across process stages, enabling root cause identification. Machine learning algorithms can identify subtle patterns preceding defect occurrence.

Inline Inspection Technology Comparison

| Inspection Type | Detection Capability | Response Time | Integration Complexity |

|---|---|---|---|

| Optical Vision | Surface defects, dimensions | <100ms | Low |

| X-ray Imaging | Internal structure, alignment | 1-5s | High |

| Ultrasonic Testing | Weld quality, delamination | <500ms | Medium |

| Thermal Imaging | Heat distribution, hot spots | <200ms | Low |

Statistical process control implementation requires careful selection of control parameters and limits. Multivariate analysis techniques prove particularly valuable for complex interactions between process variables.

Preventive Maintenance Protocols for Defect Reduction

Systematic maintenance prevents equipment degradation that leads to product defects. Condition-based maintenance strategies optimize intervention timing.

Blade replacement schedules for slitting equipment should incorporate material throughput metrics rather than simple time intervals. Edge geometry measurements guide replacement decisions.

Welding horn inspection in ultrasonic systems requires both visual examination and performance testing. Amplitude measurements under load conditions indicate horn wear progression.

Critical Maintenance Checklist by Equipment Type

- Slitting Systems: Blade sharpness, roller bearing condition, dust extraction efficiency

- Welding Stations: Horn surface condition, fixture alignment, power delivery consistency

- Filling Equipment: Needle wear, seal integrity, dispensing accuracy calibration

- Sealing Bars: Temperature uniformity, surface contamination, pressure distribution

- Formation Channels: Contact resistance, temperature sensor calibration, safety system verification

Calibration protocols must address both measurement accuracy and control system response. Drift in sensor readings can gradually shift process parameters outside optimal ranges.

Advanced Troubleshooting Techniques for Complex Defects

Some defects result from interactions between multiple process stages, requiring systematic investigation approaches. Design of experiments methodologies efficiently identify contributing factors.

Cross-functional teams combining equipment operators, quality engineers, and process specialists prove most effective for complex problem resolution. Root cause analysis tools structure investigation processes.

Defect pattern recognition across production batches often reveals subtle equipment degradation or material variation trends. Time-series analysis of quality metrics enables predictive interventions.

Conclusion

Successful defect prevention in pouch cell manufacturing machine operations requires comprehensive understanding of process interactions, systematic quality control implementation, and proactive maintenance strategies. Each production stage presents unique challenges that demand specific technical solutions.

Modern production lines integrate sophisticated monitoring and control systems, but fundamental process knowledge remains essential for effective troubleshooting. Regular training updates ensure personnel maintain current best practices as technology evolves.

Continuous improvement initiatives should focus on reducing variation before attempting to shift process means. This approach maximizes both quality and yield while minimizing production disruptions.

Glossary

- Active Material Delamination

- Separation of electrode coating from current collector foil, typically caused by mechanical stress or binder degradation

- Burr Height

- Perpendicular projection of material at slit edges, measured in micrometers from the base electrode surface

- Incremental Capacity Analysis (dQ/dV)

- Differential analysis technique plotting capacity change versus voltage to identify phase transitions and degradation mechanisms

- Heat Affected Zone (HAZ)

- Region surrounding a weld where material properties change due to thermal exposure during joining processes

- Vacuum Filling

- Electrolyte injection method using reduced pressure to remove air and enhance liquid penetration into porous structures

- Web Tension

- Controlled stretching force applied to electrode material during slitting, measured in Newtons per meter of width

- Formation Cycling

- Initial charge-discharge sequences that establish the solid electrolyte interface and activate cell chemistry

- Statistical Process Control (SPC)

- Quality methodology using statistical methods to monitor and control manufacturing process variations