Setting up a coin cell assembly laboratory requires careful selection of specialized equipment to ensure reproducible results and safe operation. From precision die sets to controlled-atmosphere gloveboxes, each component plays a critical role in producing reliable test cells for battery research and development.

This guide covers the fundamental coin cell assembly equipment needed for CR2032, CR2025, and CR2016 formats, including setup parameters, operational specifications, and quality control considerations. Whether establishing a new facility or upgrading existing capabilities, understanding equipment requirements helps optimize both capital allocation and research outcomes.

What Equipment Do You Need for Coin Cell Assembly?

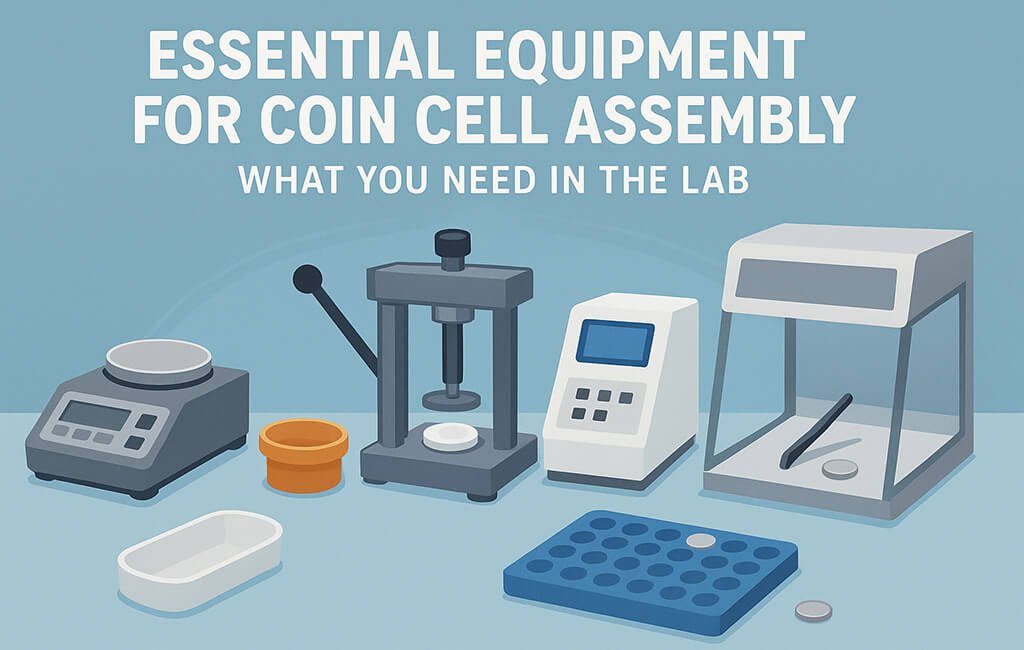

A complete coin cell assembly station requires five core equipment categories: electrode preparation tools, cell assembly fixtures, crimping systems, electrolyte handling equipment, and environmental control systems. Each category includes multiple options based on production volume, precision requirements, and budget constraints.

Beyond basic hardware, successful implementation depends on proper calibration procedures, maintenance protocols, and operator training. Equipment selection should align with specific research objectives, whether focused on materials screening, quality control testing, or prototype development.

Core Equipment Categories

Electrode preparation equipment includes precision punches, dies, and cutting systems for creating uniform electrode discs. Standard diameters range from 10mm to 16mm, with tolerance requirements typically ±0.05mm for research applications.

Assembly fixtures comprise alignment tools, spacer rings, and handling implements designed to maintain component positioning during cell construction. Spring-loaded fixtures accommodate varying stack heights while ensuring consistent pressure distribution.

Crimping systems apply controlled force to seal coin cells, with manual, pneumatic, and hydraulic options available. Force specifications typically range from 800-2000 psi depending on case material and seal requirements.

How to Select the Right Crimping Press for Coin Cells?

Crimping press selection depends on three primary factors: force capacity, pressure uniformity, and throughput requirements. Manual presses suffice for low-volume research, while pneumatic systems better serve production environments requiring consistent results across multiple cells.

Key specifications include maximum force rating (typically 1-3 tons), platen diameter (20-40mm), and pressure control resolution. Digital force monitoring capabilities enable process validation and quality documentation.

| Parameter | Manual Press | Pneumatic Press | Hydraulic Press | Application Notes |

|---|---|---|---|---|

| Force Range | 0.5-2 tons | 1-3 tons | 2-10 tons | CR2032 requires 1000-1500 psi |

| Repeatability | ±10% | ±5% | ±2% | Critical for seal integrity |

| Cycle Time | 30-60 sec | 10-20 sec | 15-30 sec | Including load/unload |

| Footprint | 0.1 m² | 0.3 m² | 0.5 m² | Benchtop vs floor-standing |

| Maintenance | Minimal | Moderate | Regular | Seal/fluid replacement |

Pressure Distribution Considerations

Uniform pressure distribution prevents case deformation and ensures consistent seal quality. Die sets should feature hardened steel construction with surface finish better than Ra 0.8 μm to minimize friction during crimping.

Alignment fixtures maintain concentricity between upper and lower dies, critical for preventing asymmetric sealing. Spring-loaded centering pins accommodate minor dimensional variations while maintaining position accuracy within ±0.1mm.

Glovebox Requirements for Battery Assembly

Inert atmosphere control represents a fundamental requirement for lithium-based coin cell assembly. Glovebox systems maintain moisture levels below 1 ppm and oxygen below 10 ppm to prevent electrolyte degradation and lithium surface passivation.

Essential glovebox features include dual-port transfer chambers, integrated gas purification systems, and pressure regulation controls. Working chamber dimensions should accommodate all assembly equipment while providing adequate manipulation space.

Atmosphere Monitoring Systems

Continuous monitoring of moisture and oxygen levels ensures consistent environmental conditions throughout assembly operations. Sensor placement near working areas provides real-time feedback for process control.

Data logging capabilities enable quality documentation and troubleshooting of atmosphere-related issues. Alarm systems alert operators to excursions beyond specified limits, preventing compromised cell builds.

What Are the Key Specifications for Electrode Cutting Tools?

Precision electrode cutting requires specialized punch and die sets maintaining dimensional tolerance within ±0.05mm. Cutting edge geometry influences both dimensional accuracy and edge quality, with optimal clearance typically 5-10% of material thickness.

Material compatibility extends beyond dimensional considerations to include chemical resistance and contamination prevention. Hardened stainless steel or tungsten carbide tooling resists wear while preventing metal particle generation.

Edge Quality Parameters

Clean, burr-free edges prevent separator puncture and ensure uniform current distribution. Visual inspection under 10-20X magnification reveals edge defects requiring tool maintenance or replacement.

Cutting force requirements vary with electrode composition and thickness. Typical values range from 50-200 N for standard cathode materials, increasing to 300-500 N for compressed anodes or current collectors.

Electrolyte Filling Equipment Options

Accurate electrolyte dispensing requires precision micropipettes or automated dispensing systems. Volume accuracy of ±1% ensures consistent cell performance while minimizing waste of expensive electrolyte formulations.

Chemical compatibility dictates material selection for all wetted components. PTFE, PEEK, and perfluoroelastomer seals resist common electrolyte solvents including EC, DMC, and EMC.

| Method | Volume Range | Accuracy | Throughput | Best Application |

|---|---|---|---|---|

| Manual Pipette | 10-1000 μL | ±1% | Low | Research/screening |

| Positive Displacement | 50-5000 μL | ±0.5% | Medium | Viscous electrolytes |

| Automated Dispenser | 1-10000 μL | ±0.3% | High | Production QC |

| Syringe Pump | 0.1-50 mL | ±0.2% | Medium | Large format cells |

Contamination Prevention

Dedicated filling equipment for each electrolyte type prevents cross-contamination between formulations. Regular cleaning protocols using appropriate solvents maintain system cleanliness.

Inline filtration removes particulates that could cause internal shorts or capacity fade. Filter materials must demonstrate chemical compatibility while maintaining specified pore size, typically 0.2-0.45 μm.

Quality Control and Testing Equipment

Dimensional verification tools including calipers and micrometers ensure component conformance to specifications. Digital instruments with data output capabilities facilitate statistical process control.

Electrical testing equipment performs initial characterization including open circuit voltage, impedance, and short circuit detection. Integration with data management systems enables comprehensive quality documentation.

Common Assembly Defects Checklist

- □ Incomplete seal – visible gaps or deformation at crimp interface

- □ Electrolyte leakage – wetness or discoloration around seal area

- □ Component misalignment – eccentric electrode placement visible through case

- □ Contamination – foreign particles or discoloration on components

- □ Insufficient compression – loose stack detectable by shake test

- □ Over-crimping – case deformation or cracking

- □ Tab damage – bent, torn, or improperly positioned current collectors

- □ Separator wrinkles – non-uniform separator placement causing thickness variations

Safety Equipment and Protocols

Personal protective equipment specific to battery assembly includes chemical-resistant gloves, safety glasses, and lab coats. Specialized handling tools prevent direct contact with reactive materials.

Emergency response equipment encompasses eyewash stations, safety showers, and appropriate fire suppression systems. Class D fire extinguishers address lithium metal hazards present in anode preparation areas.

Ventilation Requirements

Local exhaust ventilation at electrolyte handling stations prevents vapor accumulation. Flow rates of 0.5-1.0 m/s at the point of generation effectively capture organic solvent vapors.

General laboratory ventilation maintaining 6-10 air changes per hour provides dilution of background contaminants. Pressure differentials prevent migration of hazardous vapors to adjacent spaces.

Supporting Infrastructure

Compressed gas systems supply high-purity argon or nitrogen for glovebox operation. Dual-stage regulators with metal diaphragms prevent contamination while maintaining stable delivery pressure.

Vacuum systems support transfer chamber operation and component drying processes. Oil-free pumps prevent hydrocarbon contamination, with ultimate pressure specifications typically 10⁻³ torr or better.

Utilities Specifications

Electrical requirements vary by equipment configuration but typically include 120/240V single-phase and 208V three-phase circuits. Dedicated circuits prevent interference from other laboratory equipment.

Cooling water systems may be required for hydraulic press operation or glovebox heat removal. Closed-loop systems prevent mineral buildup while maintaining temperature stability.

Formation and Testing Integration

Battery cyclers perform formation protocols and characterization testing on assembled cells. Channel specifications should match expected current and voltage ranges with appropriate safety limits.

Temperature chambers enable performance evaluation across operating conditions. Integration with cycler systems allows automated temperature profiling during testing sequences.

Data acquisition systems capture comprehensive test results for analysis and reporting. Database integration facilitates correlation between assembly parameters and cell performance.

Test Protocol Considerations

Formation procedures typically involve controlled initial charging to develop stable SEI layers. Current rates of C/20 to C/10 balance formation time with layer quality.

Acceptance testing includes capacity verification, rate capability assessment, and impedance characterization. Statistical sampling plans ensure representative evaluation of production batches.

Maintenance and Calibration

Regular maintenance schedules prevent equipment degradation and ensure consistent performance. Critical items include die sharpening, seal replacement, and lubrication of moving components.

Calibration protocols verify equipment accuracy against traceable standards. Force gauges, pressure sensors, and dimensional measuring tools require periodic verification.

Troubleshooting Common Issues

- □ Inconsistent crimp force – check hydraulic fluid levels and system pressure

- □ Poor seal quality – inspect die surfaces for damage or contamination

- □ Atmosphere excursions – verify purifier regeneration and seal integrity

- □ Dispensing variations – clean or replace pipette tips and check calibration

- □ Alignment problems – adjust fixture guides and verify component dimensions

- □ Cross-contamination – review cleaning protocols and dedicate tools

- □ Measurement drift – recalibrate instruments and check environmental conditions

Conclusion

Successful coin cell assembly requires careful integration of specialized equipment, controlled environments, and validated procedures. From precision cutting tools to automated test systems, each component of the assembly line contributes to final cell quality and research reliability.

Investment in appropriate coin cell assembly equipment pays dividends through improved reproducibility, enhanced safety, and accelerated development cycles. Regular maintenance, proper training, and systematic quality control ensure these benefits persist throughout the equipment lifecycle.

As battery technology continues advancing, assembly equipment capabilities must evolve accordingly. Staying current with equipment developments while maintaining proven protocols balances innovation with reliability in battery research and development operations.

Glossary

- Crimping Force

- Mechanical pressure applied to seal coin cell cases, typically measured in PSI or tons, ensuring hermetic closure without component damage.

- Glovebox Atmosphere

- Controlled environment maintaining <1 ppm H₂O and <10 ppm O₂ to prevent degradation of moisture-sensitive battery materials.

- Die Clearance

- Gap between punch and die cutting edges, typically 5-10% of material thickness, affecting cut quality and tool life.

- Formation Protocol

- Initial charge/discharge cycles applied to new cells to develop stable solid-electrolyte interface (SEI) layers.

- Transfer Chamber

- Airlock system allowing material introduction to glovebox while maintaining atmospheric integrity through pump-purge cycles.

- Separator

- Microporous membrane preventing direct electrode contact while allowing ionic transport, typically polyolefin or ceramic-coated polymer.

- Current Collector

- Conductive substrate supporting active electrode materials, typically aluminum for cathodes and copper for anodes.

- Electrolyte

- Ionic conductor comprising lithium salt dissolved in organic carbonate solvents, enabling charge transport between electrodes.