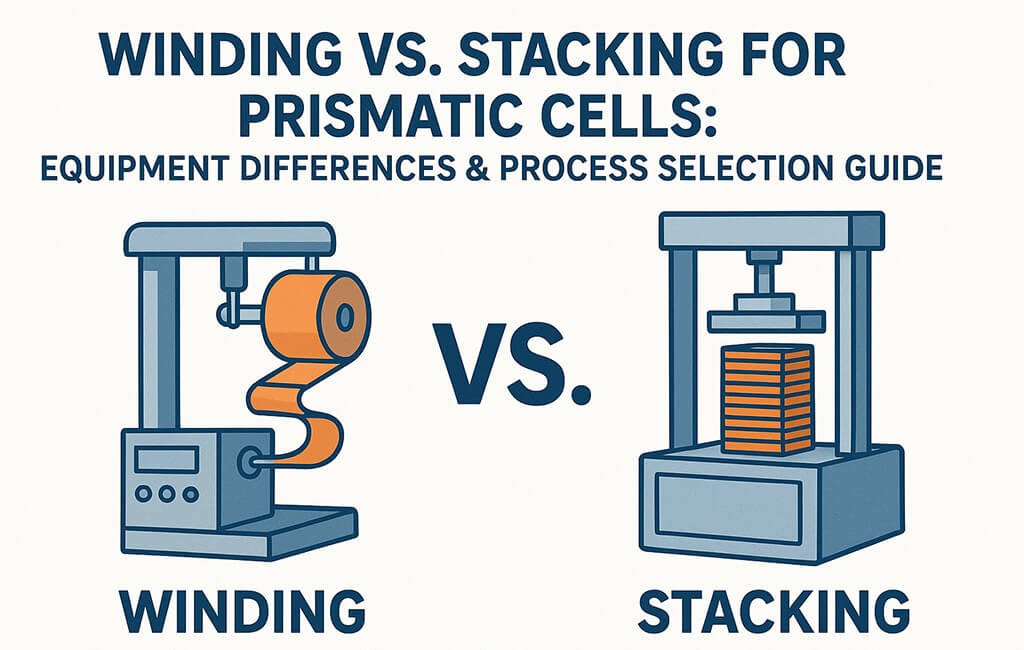

Prismatic cell manufacturing machines employ two primary assembly methods: continuous winding and discrete stacking. Each approach requires distinct equipment configurations, process parameters, and quality control strategies.

This guide examines the technical specifications, operational differences, and selection criteria for winding and stacking equipment in prismatic cell production lines. Equipment engineers and procurement teams can use these parameters to match assembly methods with product requirements and production targets.

What are the fundamental differences between winding and stacking for prismatic cell manufacturing machines?

Winding systems use continuous electrode webs with separator material to create jellyroll structures, while stacking systems assemble discrete electrode sheets in alternating layers. These methods differ in equipment design, process control, and output characteristics.

Winding Equipment Configuration

Winding machines integrate tension control systems, web guidance mechanisms, and mandrel assemblies. The equipment maintains consistent web tension across multiple material paths while controlling winding speed and compression.

Key subsystems include unwinding stations for anode, cathode, and separator rolls; dancer roller assemblies for tension regulation; and servo-driven winding heads with programmable acceleration profiles. Edge alignment sensors and web tracking systems ensure precise layer registration throughout the winding cycle.

Stacking Equipment Configuration

Stacking machines utilize pick-and-place mechanisms, vision systems, and compression stations. The equipment handles pre-cut electrode sheets with high positional accuracy while maintaining separator integrity between layers.

Primary components include sheet feeding magazines, vacuum gripper assemblies, alignment stages with sub-millimeter precision, and progressive compression mechanisms. Vision systems verify sheet placement and detect defects before each stacking operation.

Process Parameter Specifications and Operating Ranges

| Parameter | Winding Systems | Stacking Systems | Application Notes |

|---|---|---|---|

| Electrode Width Tolerance | ±0.2-0.5 mm | ±0.1-0.3 mm | EV cells require tighter tolerances |

| Web/Sheet Tension | 0.5-2.0 N/cm | N/A (vacuum handling) | Material-dependent optimization |

| Processing Speed | 5-20 m/min | 10-40 sheets/min | Format size affects throughput |

| Alignment Accuracy | ±0.5-1.0 mm | ±0.2-0.5 mm | Critical for tab positioning |

| Compression Force | 50-200 N/cm² | 100-300 N/cm² | Chemistry-specific requirements |

| Separator Overhang | 1-3 mm per side | 2-4 mm per side | Safety margin for internal shorts |

How do equipment requirements differ between winding and stacking methods?

Winding equipment emphasizes continuous material handling and tension control, while stacking equipment prioritizes discrete sheet positioning and layer-by-layer assembly. These fundamental differences drive distinct equipment specifications and auxiliary system requirements.

Material Handling Systems

Winding lines require unwinding stations with brake control, splice tables for continuous operation, and accumulator systems. Web tension must remain consistent across varying roll diameters and splice transitions.

Stacking lines need sheet feeding magazines, separator dispensing units, and buffer storage systems. Sheet singulation mechanisms must handle electrode materials without damage or contamination.

Quality Control Integration

Winding systems integrate web inspection cameras, thickness measurement sensors, and tension monitoring. Defect detection occurs in real-time during continuous web movement.

Stacking systems employ vision inspection at multiple stages: incoming sheet verification, placement accuracy checking, and stack height measurement. Each layer undergoes individual quality assessment before assembly progression.

Equipment Selection Criteria for Different Cell Formats

Cell geometry, capacity requirements, and production volume influence equipment selection. Format-specific considerations determine optimal assembly methods and equipment configurations.

Small Format Cells (Under 20Ah)

Winding equipment offers advantages for smaller prismatic cells through higher production speeds and simplified handling. Mandrel designs accommodate various cell thicknesses without major retooling.

Equipment specifications include narrow web handling capabilities (50-150mm width), high-speed winding heads (up to 30 m/min), and compact footprints. Tension control systems manage lighter web tensions suitable for thinner electrodes.

Large Format Cells (Over 50Ah)

Stacking equipment provides superior control for large-format cells with multiple electrode pairs. Sheet-based assembly enables flexible layer counts and easier integration of multiple tabs.

Equipment requirements include extended magazine capacity, reinforced compression systems, and enlarged vision fields. Multi-station configurations allow parallel processing of different electrode types.

What are the critical troubleshooting points for prismatic cell manufacturing machines?

Common production issues vary between winding and stacking equipment. Systematic troubleshooting protocols address equipment-specific failure modes and quality deviations.

Winding Equipment Troubleshooting Checklist

- Telescoping: Check web tension balance, verify roller parallelism, calibrate edge sensors

- Wrinkles: Adjust spreader roller angles, optimize tension profiles, inspect web path alignment

- Layer shifting: Validate mandrel concentricity, review acceleration parameters, check brake response

- Tab misalignment: Calibrate tab insertion timing, verify web tracking accuracy, adjust welding positions

- Separator damage: Reduce nip pressure, check roller surface condition, optimize threading procedures

Stacking Equipment Troubleshooting Checklist

- Sheet mispicks: Clean vacuum cups, adjust pick pressure, verify magazine alignment

- Stack tilting: Check compression plate parallelism, validate sheet placement sequence, measure platform flatness

- Edge alignment errors: Calibrate vision system, clean alignment stops, verify gripper centering

- Separator folding: Reduce placement speed, optimize vacuum release timing, check separator tension

- Electrode damage: Adjust gripper pressure, inspect contact surfaces, review acceleration profiles

Process Optimization Strategies

Equipment optimization focuses on throughput enhancement, quality improvement, and waste reduction. Method-specific approaches address the unique characteristics of each assembly process.

Winding Process Optimization

Speed ramping profiles balance production rate with winding quality. Progressive acceleration during initial rotations prevents core slippage, while controlled deceleration minimizes end-of-wind defects.

Tension tapering compensates for roll diameter changes and maintains consistent layer compression. Programmable tension profiles adjust for material variations and environmental conditions.

Mandrel extraction sequences prevent jellyroll spring-back through controlled support and compression maintenance. Automated extraction systems coordinate mandrel withdrawal with external cell compression.

Stacking Process Optimization

Placement sequence optimization reduces cycle time through efficient motion planning. Parallel processing of electrode preparation and stacking operations maximizes equipment utilization.

Compression staging applies graduated pressure during stack building. Initial light compression maintains alignment, while final compression achieves target density without electrode damage.

Vision system teaching routines adapt to material variations and batch changes. Automated threshold adjustment maintains detection reliability across different electrode types.

Integration with Upstream and Downstream Processes

Assembly equipment interfaces with electrode production, tab welding, and cell finishing systems. Coordination requirements vary between winding and stacking configurations.

Upstream Integration Requirements

Winding systems require continuous electrode supply with splice preparation capabilities. Roll change procedures must minimize production interruption while maintaining web tension.

Stacking systems need synchronized sheet cutting and buffer management. Cut-to-length accuracy directly impacts stacking precision and cell consistency.

Material tracking systems maintain lot traceability through both assembly methods. Barcode or RFID integration enables electrode-to-cell genealogy recording.

Downstream Integration Requirements

Tab welding equipment must accommodate different electrode configurations. Winding produces continuous tab strips, while stacking creates discrete tab arrays.

Formation and testing protocols adjust for assembly method differences. Wound cells may require different conditioning cycles than stacked cells due to internal stress distributions.

Electrolyte filling systems compensate for varying pore structures. Winding tension affects porosity distribution differently than stacking compression.

Equipment Maintenance and Validation Protocols

Preventive maintenance schedules address method-specific wear patterns and failure modes. Validation protocols ensure continued compliance with process specifications.

Winding Equipment Maintenance

Roller bearing inspection intervals depend on web tension and speed profiles. High-tension applications require more frequent bearing replacement and alignment verification.

Web path cleaning removes electrode particle accumulation. Scheduled cleaning prevents material buildup that causes web tracking errors and tension variations.

Mandrel surface conditioning maintains proper friction characteristics. Surface treatment renewal ensures consistent core formation and extraction force.

Stacking Equipment Maintenance

Gripper component replacement follows pick count metrics. Vacuum cup wear affects pickup reliability and requires periodic inspection.

Vision system calibration maintains placement accuracy. Monthly calibration routines verify camera alignment and measurement accuracy.

Magazine adjustment compensates for sheet dimension variations. Guide rail positioning accommodates different electrode batches while maintaining feed reliability.

Glossary

- Mandrel:

- Cylindrical or flat winding core that defines the jellyroll center cavity and provides initial winding support

- Web tension:

- Controlled pulling force applied to electrode and separator materials during continuous winding operations

- Stack compression:

- Applied pressure that consolidates electrode layers and maintains electrical contact within the cell assembly

- Tab welding:

- Ultrasonic or laser joining process that connects electrode current collectors to external cell terminals

- Vision alignment:

- Optical measurement system that verifies electrode positioning accuracy during stacking operations

- Dancer roller:

- Moveable roller assembly that maintains constant web tension through position feedback control

- Sheet singulation:

- Mechanical separation process that feeds individual electrode sheets from stacked magazines

- Formation cycling:

- Initial charge-discharge sequences that establish the solid electrolyte interface and activate cell chemistry