The global prismatic lithium-ion battery market is poised to reach $1800 billion by 2025, driven by soaring demand from electric vehicles (EVs) and energy storage systems (ESS). This rectangular cell format, celebrated for its space efficiency and structural stability, relies on a highly integrated manufacturing process where equipment precision directly dictates performance and safety. Yet, industry professionals frequently grapple with fragmented understanding of equipment functions and struggles to align machinery specifications with process requirements. This article dissects the three core manufacturing stages, presenting 2025’s latest equipment technologies, technical parameters, and brand applications—including insights into XHS Battery Machine, a rising player in specialized cell production gear—to bridge these gaps.

1. Front-End Process: Foundation of Electrode Quality

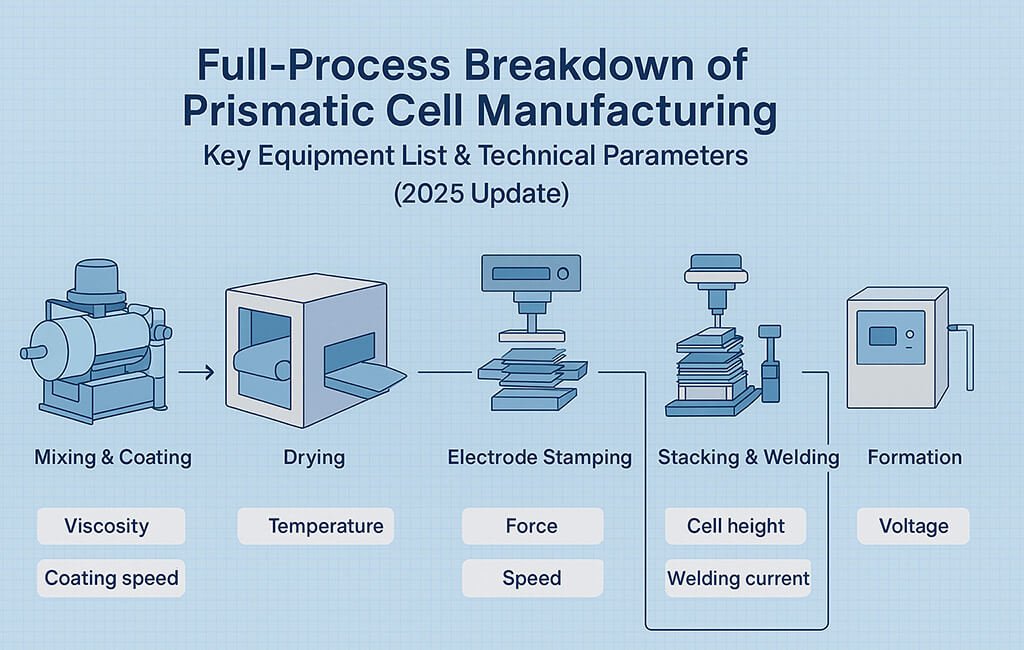

The front-end process—encompassing mixing and coating—establishes the electrochemical performance of prismatic cells. Material uniformity and coating consistency at this stage directly impact energy density and cycle life, making equipment selection critical for high-volume, high-quality production.

1.1 Mixing Systems: Slurry Homogeneity Engine

Mixing transforms active materials (e.g., LiFePO₄ for cathodes, graphite for anodes), conductive additives, and binders into uniform slurries. The 2025 generation of mixers prioritizes continuous processing and precise viscosity control to support EV and ESS scale-up.

| Parameter | 2025 Benchmark | Function Significance |

|---|---|---|

| Mixing Type | Continuous dual-helix grinding | Eliminates batch inconsistencies common in traditional planetary mixers |

| Viscosity Control Accuracy | ±5 mPa·s | Ensures stable slurry flow during coating, preventing uneven electrode thickness |

| Vacuum Degree | ≤ -98 kPa | Removes air bubbles to avoid micro-voids in electrodes |

| Processing Capacity | Up to 2000 L/h | Matches the throughput of high-speed coating lines in EV battery plants |

Representative Brands & Applications:

- Xindao Intelligent (China): Its CXJ-2000 continuous mixer integrates real-time viscosity monitoring, widely adopted by CATL for 46-series prismatic cell production.

- Manz Germany: The MixCoat 300 system excels in high-nickel cathode slurry preparation, used by LG Energy Solution for premium EV cells.

- XHS Battery Machine (China): The XHS-MX1800 continuous mixer targets mid-scale LiFePO₄ prismatic cell manufacturers, offering 1800 L/h capacity and integrated slurry temperature control (±1°C) to reduce material waste—deployed in regional ESS battery plants in Southeast Asia.

1.2 Coating Machines: Precision Layer Deposition

Coating applies slurry onto current collectors (aluminum for cathodes, copper for anodes) with micron-level accuracy. 2025 equipment focuses on speed-quality balance and adaptive control to handle wide foils (up to 1.6m) common in prismatic designs.

| Parameter | 2025 Benchmark | Function Significance |

|---|---|---|

| Coating Method | Slot-die with air pressure compensation | Delivers uniform layers across 1.6m-wide foils (standard for prismatic formats) |

| Coating Thickness Accuracy | ±2 μm | Critical for maintaining consistent energy density in stacked prismatic electrodes |

| Line Speed | 150 m/min | 30% higher than 2023 models, supporting 50GWh annual production lines |

| Drying Efficiency | Solvent residue < 50 ppm | Uses multi-zone hot air circulation to prevent electrode warping |

Representative Brands & Applications:

- Hirano Japan: The HC-800 coating machine’s edge-trimming technology reduces material waste by 12%, ideal for consumer electronics prismatic cells (e.g., smartphones, laptops).

- Lith Corporation (China): Specializes in LiFePO₄ prismatic cell coating equipment, deployed in grid-scale ESS production for State Grid projects.

2. Mid-End Process: Structural Integrity & Assembly Precision

Mid-end operations—winding/stacking and welding—determine the prismatic cell’s structural stability and current conduction efficiency. Stacking remains dominant for high-energy prismatic cells, while welding technology advances toward non-destructive precision to avoid casing damage.

2.1 Winding/Stacking Equipment: Core Forming Machinery

Stacking assembles anode-separator-cathode layers in precise sequences, while winding creates rectangular “jelly rolls” for compact prismatic designs. 2025 equipment achieves sub-micron positioning to minimize internal resistance and improve cycle life.

| Equipment Type | Key Parameter | 2025 Benchmark | Application Focus |

|---|---|---|---|

| Stacking Machine | Positioning Accuracy | ±3 μm | High-energy-density EV prismatic cells (e.g., 4695, 590 prismatic formats) |

| Cycle Time | 0.15 s/layer | ||

| Layer Count Capacity | Up to 200 layers | ||

| Winder | Winding Speed | 2200 rpm | Compact prismatic cells for wearables (e.g., smartwatches) |

| Tension Control | ±0.5 N |

Representative Brands & Applications:

- Schaeffler (Germany): Its 2025 stacking system integrates magnetic levitation transport (2m/s speed) for BMW’s 4695 prismatic cell production, enabling 200 PPM (pieces per minute) capacity.

- Lead Intelligent (China): The LS-1800 stacker supports 180-layer assemblies, used in BYD’s blade battery lines for EVs.

- XHS Battery Machine (China): The XHS-ST150 stacking machine targets mid-size EV prismatic cells (e.g., 38120 format), offering ±4 μm positioning accuracy and 0.16 s/layer cycle time. It is currently used by Gotion High-Tech for its entry-level EV battery modules, with a focus on cost-effectiveness and easy maintenance.

2.2 Welding Equipment: Hermetic & Conductive Joining

Welding connects current collectors to terminals and seals casings, with fiber laser technology leading in 2025 for prismatic cells’ aluminum/steel housings—critical for preventing electrolyte leakage.

| Parameter | 2025 Benchmark | Function Significance |

|---|---|---|

| Laser Wavelength | 1064 nm (fiber laser) | Optimized for aluminum casing penetration without thermal damage |

| Welding Precision | ±0.02 mm | Ensures hermetic sealing to prevent electrolyte leakage |

| Throughput | 280 PPM | Matches high-speed stacking lines via turret-based processing |

| Post-Weld Resistance | < 5 mΩ | Minimizes energy loss in high-current EV applications |

Representative Brands & Applications:

- Yihui Laser (China): Its flying welding system achieves 80% laser utilization, deployed in SK On’s prismatic cell pilot lines for next-gen EVs.

- Dukane (USA): Specializes in ultrasonic welding for small-format prismatic cells in consumer electronics (e.g., tablets).

3. Back-End Process: Activation & Quality Assurance

The back-end process—electrolyte injection, formation, and encapsulation—activates the cell’s electrochemical properties and ensures long-term reliability. 2025 technologies emphasize environmental control (e.g., ultra-dry conditions) and rapid aging to shorten production cycles.

3.1 Electrolyte Injection Systems: Controlled Wetting

Injection introduces LiPF₆-based electrolyte into the cell under strictly dry conditions to enable ion transport. Precision here directly impacts cell capacity and cycle stability.

| Parameter | 2025 Benchmark | Function Significance |

|---|---|---|

| Injection Accuracy | ±0.01 mL | Precisely controls electrolyte-to-electrode ratio for consistent performance |

| Chamber Dew Point | < -45 °C | Prevents electrolyte hydrolysis in prismatic cells’ large internal volumes |

| Vacuum Level | 10⁻³ Pa | Removes air to ensure full electrode wetting |

| Cycle Time | 8 s/cell | Supports 450 cells per hour per station |

Representative Brands & Applications:

- TMAX Battery Equipments (China): Its vacuum injection system is used in LiFePO4 prismatic cell production for industrial AGVs (automated guided vehicles).

- Nagano Keiki (Japan): Specializes in precision metering pumps for high-nickel prismatic cells (e.g., NCM 811) used in luxury EVs.

- XHS Battery Machine (China): The XHS-EJ120 electrolyte injection system is designed for small to mid-format prismatic cells (e.g., 26700 for portable ESS), offering ±0.02 mL accuracy and a compact footprint. It is integrated into Great Wall Motors’ auxiliary battery production lines, where space efficiency is a priority.

3.2 Formation & Aging Equipment: Performance Activation

Formation creates a stable solid electrolyte interphase (SEI) layer, while aging identifies early defects (e.g., capacity fade, internal short circuits). 2025 equipment integrates digital twins for real-time performance monitoring.

| Parameter | 2025 Benchmark | Function Significance |

|---|---|---|

| Formation Current Range | 0.1C – 5C | Accommodates fast activation of high-power prismatic cells |

| Voltage Control Accuracy | ±1 mV | Ensures uniform SEI layer formation across cell batches |

| Aging Temperature Range | -20°C to 60°C | Simulates real-world operating conditions for EV and ESS applications |

| Data Sampling Rate | 100 Hz | Captures subtle capacity fade during aging for quality screening |

Representative Brands & Applications:

- Arbin Instruments (USA): Its BT2000 system with AI-driven defect detection is used by Samsung SDI for prismatic cell validation and pre-production testing.

- Neware (China): Offers modular formation systems scalable from lab testing (10-cell capacity) to 10GWh production lines.

3.3 Encapsulation Equipment: Final Protection

Encapsulation hermetically seals the prismatic casing, with laser welding dominating 2025 production for its reliability and compatibility with aluminum/steel housings.

| Parameter | 2025 Benchmark | Function Significance |

|---|---|---|

| Seal Strength | > 5 MPa | Resists internal pressure buildup during cycling |

| Leak Rate | < 1×10⁻⁹ Pa·m³/s | Passes helium leak detection per IEC 62133 standards (global battery safety benchmark) |

| Cycle Time | 6 s/cell | Matches downstream testing line throughput |

| Compatibility | Aluminum/steel casings | Adapts to different prismatic cell form factors |

Representative Brands & Applications:

- Hirano Japan: Its laser sealing system is favored for consumer electronics prismatic cells requiring ultra-thin casings (e.g., 0.3mm aluminum).

- Schaeffler (Germany): Integrates encapsulation with post-seal helium testing for automotive prismatic cells, ensuring compliance with ISO 12405 (EV battery safety standards).

2025 Technology Trends & Equipment Selection Guidelines

The 2025 prismatic cell manufacturing landscape is defined by three key trends: digitization (digital twins in formation equipment to optimize SEI layer formation), material adaptability (compatibility with high-nickel NCM and low-cost LiFePO₄ chemistries), and localization (regional supply chains driven by policies like the EU Battery Act and U.S. Inflation Reduction Act).

To address fragmented equipment cognition and align machinery with process needs, manufacturers should follow these guidelines:

- Map Equipment to Material Systems: High-nickel cathodes (e.g., NCM 910) require stricter moisture control (dew point < -45°C) in injection systems, while LiFePO₄ prismatic cells prioritize stacking precision to maximize energy density.

- Align Throughput Parameters: Ensure front-end coating speed (150 m/min) matches mid-end stacking capacity (200 PPM) and back-end injection cycle time (8 s/cell) to avoid production bottlenecks. For example, XHS’s XHS-MX1800 mixer (1800 L/h) pairs well with its XHS-ST150 stacker (0.16 s/layer) for mid-scale lines.

- Leverage Brand Specializations: Chinese suppliers like Xindao and XHS Battery Machine excel in cost-effective, high-volume solutions for LiFePO₄ and entry-level EV cells; Japanese/German brands (Hirano, Manz) lead in precision for high-nickel and consumer electronics applications.

By integrating these equipment insights with process requirements, manufacturers can navigate the complexity of prismatic cell production and capitalize on the $1800 billion market opportunity. The synergy between equipment precision and process design remains the cornerstone of delivering safe, high-performance prismatic cells across EV, ESS, and consumer electronics applications.