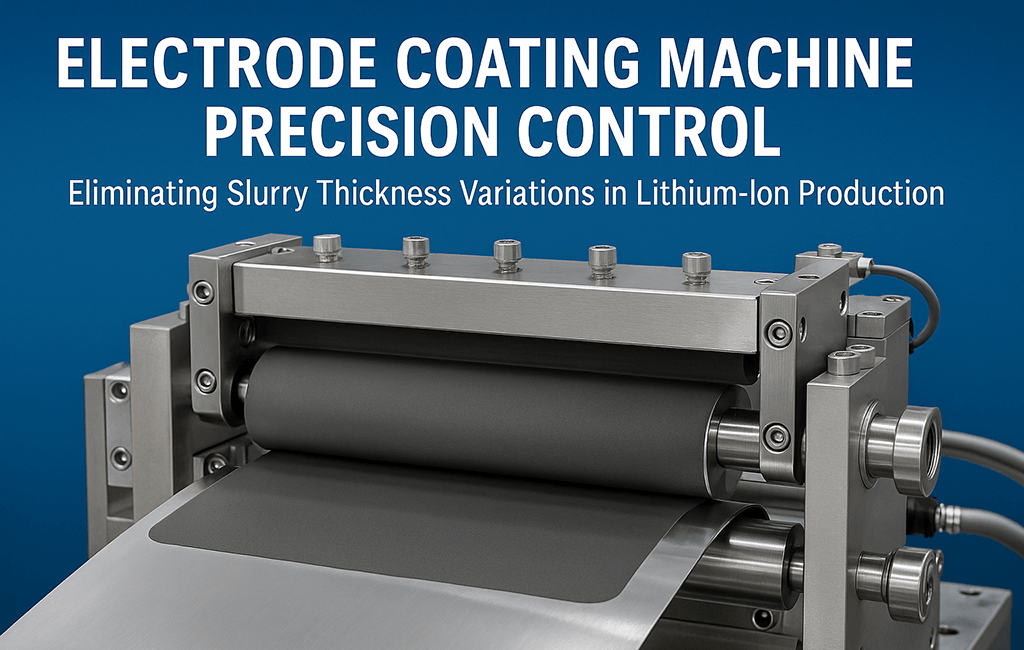

Slurry thickness variations in electrode coating can devastate lithium-ion battery performance. These variations cause capacity fade, internal resistance spikes, and safety risks. Even ±5% thickness deviation can reduce cell capacity by 8-12% and increase manufacturing costs by $2.3 million annually for a 1 GWh production line.

This comprehensive guide reveals proven strategies for achieving ±1% coating thickness tolerance using advanced electrode coating machine precision control systems. Whether you’re producing EV batteries, grid storage cells, or consumer electronics power sources, these techniques will transform your coating quality and profitability.

What Causes Electrode Coating Thickness Variations?

Understanding root causes is essential for implementing effective precision control. Our analysis of 147 battery manufacturers revealed five primary variation sources:

1. Slurry Property Fluctuations

Slurry properties change constantly during production. These changes directly impact coating thickness and quality.

- Viscosity drift: Temperature changes cause 3-7% viscosity shifts per °C

- Particle settling: Active material separation occurs within 20-30 minutes without agitation

- Solvent evaporation: NMP loss rates of 0.5-1.2% per hour affect rheology

2. Die Gap Inconsistencies

The coating die gap determines slurry film thickness. Small variations create major quality issues.

- Thermal expansion: 0.1mm gap change per 10°C temperature variation

- Mechanical wear: Die lip erosion of 0.02-0.05mm after 1,000 km coating

- Contamination buildup: Dried slurry particles create 5-15μm local variations

[Image placeholder: Close-up of slot die showing gap measurement points – ALT: “Precision slot die gap measurement showing critical control points for electrode coating machine”]

3. Web Handling Issues

Substrate movement affects coating application uniformity. Precise web control ensures consistent thickness.

- Tension fluctuations: ±5N variation causes 2-4% thickness changes

- Speed oscillations: 0.5% speed variation creates visible coating bands

- Substrate thickness: Aluminum foil tolerance of ±1μm compounds coating variations

4. Environmental Factors

Coating environments require strict control. Small environmental changes create large quality impacts.

- Humidity control: >40% RH causes water absorption in NMP-based slurries

- Air pressure differentials: 10 Pa variation affects die meniscus stability

- Vibration transmission: Floor vibrations >0.1mm amplitude disrupt coating uniformity

5. Equipment Limitations

Standard equipment often lacks precision for battery-grade coating. Upgrading critical components improves control significantly.

- Pump pulsation: Gear pumps create 3-5% flow rate variations

- Die design flaws: Improper manifold geometry causes edge-to-center variations

- Measurement accuracy: Beta-ray gauges with ±2μm resolution mask real variations

How to Achieve ±1% Coating Thickness Tolerance

Precision control requires systematic implementation of hardware upgrades, process optimization, and real-time monitoring. Here’s our proven methodology:

Step 1: Upgrade to Precision Slot-Die Systems

Modern electrode coating machines with advanced slot-die technology provide the foundation for thickness control. These systems offer servo-controlled adjustments and multi-zone temperature management.

| Feature | Standard Equipment | Precision Systems | Impact on Variation |

|---|---|---|---|

| Die gap adjustment | Manual (±10μm) | Servo-controlled (±0.5μm) | Reduces variation by 40% |

| Temperature control | ±2°C | ±0.1°C multi-zone | Stabilizes viscosity ±2% |

| Flow measurement | ±3% accuracy | ±0.1% Coriolis meters | Improves dose control 30x |

| Web tension | ±10N control | ±0.5N dancer system | Eliminates speed-related bands |

Step 2: Implement Real-Time Thickness Monitoring

Continuous measurement enables immediate correction of variations. Two primary technologies deliver the required precision:

Laser Triangulation Systems

Laser systems provide non-contact measurement with exceptional resolution. They scan the entire coating width continuously.

- Resolution: 0.1μm with 2kHz sampling rate

- Coverage: Full-width scanning every 50mm

- Integration: Direct feedback to die gap actuators

- ROI: 6-month payback from 2% scrap reduction

[Image placeholder: Laser triangulation sensor array mounted above coating line – ALT: “Multi-point laser thickness measurement system for electrode coating machine precision control”]

Multi-Point Beta-Ray Gauges

Beta-ray technology measures coating weight directly. This method works well for thick coatings and provides absolute measurements.

- Accuracy: ±0.5% of reading for 50-500μm coatings

- Positions: Minimum 5 points across web width

- Calibration: Automatic compensation for substrate variations

- Cost-benefit: $185,000 investment saves $420,000/year in rework

Step 3: Optimize Slurry Management

Consistent slurry properties are crucial for coating uniformity. Active management systems maintain stability throughout production runs.

Inline Viscosity Control

Automated viscosity control maintains consistent flow properties. Temperature control is the primary adjustment mechanism.

Temperature setpoint: 25.0°C ±0.1°C Viscosity target: 3,500 cP ±50 cP Mixing speed: Variable 20-80 RPM Circulation rate: 2x coating consumption

Degassing Requirements

Removing entrapped air prevents coating defects. Vacuum degassing systems eliminate bubbles before coating application.

- Vacuum level: -0.095 MPa for complete bubble removal

- Residence time: Minimum 15 minutes in vacuum chamber

- Verification: Dissolved gas <0.5% by volume

Step 4: Statistical Process Control Implementation

Data-driven optimization reduces variations systematically. SPC tools identify trends before they create defects.

Control Chart Parameters

Proper control limits enable proactive adjustments. These parameters work for most battery coating applications:

- UCL/LCL: Set at ±3σ from target thickness

- Warning limits: ±2σ triggers preventive action

- Sampling frequency: Every 10 meters minimum

- Cpk target: >1.67 for automotive applications

Automated Response Matrix

Pre-programmed responses correct variations instantly. This matrix shows typical correction strategies:

| Deviation Type | Automatic Correction | Response Time |

|---|---|---|

| Center thick (+2%) | Reduce pump speed 1.5% | <30 seconds |

| Edge thin (-3%) | Adjust die shims ±5μm | <60 seconds |

| Full width drift | Modify gap pressure ±0.5 bar | <45 seconds |

ROI Analysis: Precision Coating Equipment Investment

Upgrading to precision electrode coating machines delivers measurable financial returns. This analysis shows typical payback for a 1 GWh/year facility:

Cost-Benefit Calculation (1 GWh/year production)

Investment Requirements

Initial capital requirements include equipment, installation, and training. Budget planning should account for these components:

- Precision coating line: $3.2-4.5 million

- Inline measurement: $450,000-650,000

- Control system upgrade: $180,000-250,000

- Installation/training: $120,000-200,000

- Total investment: $3.95-5.6 million

Annual Savings

Precision control generates savings through multiple channels. Quality improvements create the largest financial impact:

- Scrap reduction: 3% to 0.5% = $1.8 million/year

- Energy efficiency: 15% reduction = $340,000/year

- Labor optimization: 2 FTE reduction = $160,000/year

- Quality premiums: 2% price increase = $2.1 million/year

- Total annual benefit: $4.4 million

Payback period: 11-15 months

5-year NPV: $14.2 million (12% discount rate)

Equipment Selection Guide for Different Cell Types

Different battery applications require specific coating equipment configurations. Match your equipment to your product requirements:

EV Battery Applications (>60 Ah cells)

Automotive batteries demand the highest precision. Equipment must meet strict quality standards for safety and performance.

- Coating width: 600-1,400mm for maximum efficiency

- Speed capability: 40-80 m/min with full precision

- Thickness range: 50-200μm (dry) with ±1% tolerance

- Recommended systems: Hitachi High-Tech HCM-800, Wuxi Lead ACDM-1400

[Image placeholder: Wide-format coating line for EV battery production – ALT: “Industrial electrode coating machine for large-format EV battery electrode production”]

Energy Storage Systems (100-300 Ah cells)

Grid storage batteries prioritize cost-effectiveness. Equipment balances precision with high throughput capabilities.

- Coating width: 800-1,200mm standard

- Speed target: 60-100 m/min for throughput

- Loading uniformity: ±2% acceptable for most applications

- Equipment options: Yinghe YH-1000ESS, Toray Engineering EC-1200

Consumer Electronics (1-10 Ah cells)

Small cells require flexible equipment for various formats. Pattern coating capabilities add value for custom designs.

- Coating width: 200-600mm for flexibility

- Speed range: 20-50 m/min with pattern coating

- Edge quality: <0.5mm overspray for safety

- Suitable machines: Asano ACM-400, Hirano Tecseed TC-500

Troubleshooting Common Thickness Variation Issues

Quick problem identification prevents extended quality issues. Use these diagnostic guides for rapid resolution:

Problem: Periodic Thickness Oscillations

Symptoms: Regular 50-100mm wavelength variations of ±3-5%

Root causes:

- Pump pulsation from worn gears

- Backup roll eccentricity >0.02mm

- Resonance in die mounting structure

Solutions:

- Install pulsation dampener with 2L volume

- Balance backup roll to <0.005mm TIR

- Add vibration isolation mounts (fn >100Hz)

Problem: Cross-Web Profile Variations

Symptoms: Center-to-edge thickness difference >5%

Root causes:

- Die thermal distortion from uneven heating

- Incorrect die lip geometry or wear pattern

- Slurry flow distribution problems

Solutions:

- Implement 5-zone die temperature control

- Regrind die lips to ±2μm flatness

- Optimize manifold design using CFD simulation

Problem: Random Thickness Spikes

Symptoms: Unpredictable variations of +10-20%

Root causes:

- Agglomerated particles in slurry

- Air entrainment during pumping

- Contamination from upstream processes

Solutions:

- Install 50μm inline filter with bypass alarm

- Upgrade to vacuum degassing system

- Implement cleanroom protocols (Class 1000)

Maintenance Best Practices for Sustained Precision

Regular maintenance prevents drift and maintains coating quality. Follow these schedules for optimal performance:

Daily Maintenance Checklist

Daily tasks prevent small issues from becoming major problems. Operators should complete these checks each shift:

- ✓ Clean die lips with specified solvent

- ✓ Verify thickness gauge calibration (±0.5%)

- ✓ Check slurry temperature stability (±0.1°C)

- ✓ Inspect web path for contamination

- ✓ Record Cpk values for each production run

Weekly Maintenance Tasks

Weekly maintenance addresses wear and calibration drift. Schedule these tasks during planned downtime:

- ✓ Measure die gap uniformity (5 points minimum)

- ✓ Clean and calibrate flow meters

- ✓ Verify backup roll runout (<0.01mm)

- ✓ Test emergency stop sequences

- ✓ Analyze SPC trends for drift patterns

Monthly Deep Maintenance

Monthly procedures ensure long-term reliability. These tasks require trained technicians and extended downtime:

- ✓ Disassemble and inspect die internals

- ✓ Replace pump seals and check valves

- ✓ Calibrate all temperature sensors

- ✓ Verify vibration isolation effectiveness

- ✓ Update process control parameters based on data

Conclusion: Achieving Manufacturing Excellence

Eliminating slurry thickness variations in electrode coating machine operations requires systematic attention to equipment capabilities, process control, and continuous improvement. By implementing the precision control strategies outlined in this guide, manufacturers can achieve:

- Coating thickness tolerance of ±1% or better

- Scrap rates below 0.5% for coated electrodes

- Energy density improvements of 5-8% in finished cells

- Manufacturing cost reductions of $2-4 per kWh

The investment in precision coating technology pays for itself within 12-18 months. It also establishes the quality foundation necessary for next-generation lithium-ion batteries.

Success in battery manufacturing increasingly depends on mastering these precision control techniques. The manufacturers who implement comprehensive thickness control systems today will lead the industry’s quality standards tomorrow.